There are six points for attention in the setting of preheat initial speed for steel CNC table flame cutting machine.

1. the power of the preheating and cutting flame (acetylene flow and oxygen flow) increases with the increase of the thickness of the steel plate.

2. When using diffuse nozzle and oxygen curtain nozzle to cut steel plate whose thickness is less than 20 mm, the flame power should be higher, so as to accelerate the incision leading edge heating to the burning point, so as to obtain a higher cutting speed.

3. When cutting thick steel plate with steel CNC table flame cutting machine, the flame should use light carbonization flame to avoid the upper edge of the incision from melting down, and at the same time can make the outer flame longer.

4. When cutting the groove with a single cutting nozzle, the slag is blown to the outside of the incision. In order to supplement the heat, the power of the flame should be increased.

5. When cutting steel with high carbon content or alloy element content, the preheating flame power of numerical control table flame cutting machine is higher because of its higher burning point.

6. Steel CNC table flame cutting machine uses LPG or natural gas as fuel gas, because of its low flame temperature, preheating time is longer; cutting small-sized parts and other occasions that need frequent preheating and cutting, in order to improve cutting efficiency, the flame can be adjusted to oxidation flame, and then restored to neutral flame after cutting.

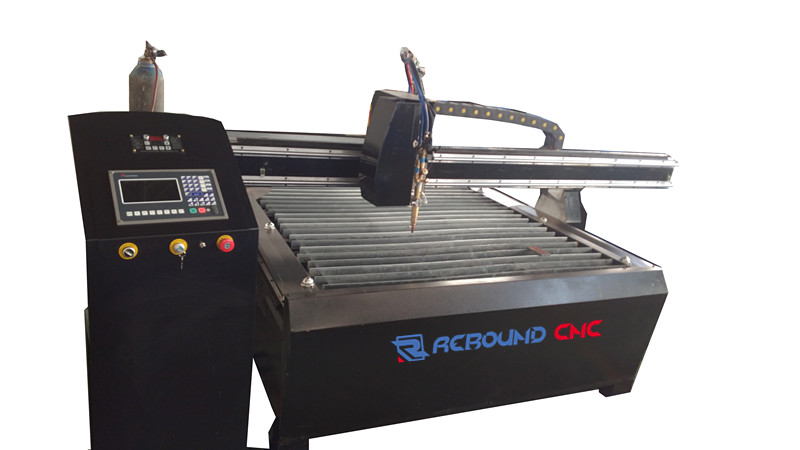

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China