Concerning the use of CNC plasma cutting machine details of attention, just contacted plasma cutting personnel suggested to fully grasp the CNC plasma cutting machine each part of the function, parameter settings and some matters needing attention.

When choosing the plasma power supply of NC plasma cutting machine, the user is advised to choose the right power supply according to his own processing requirements, such as the material, thickness and cutting speed of the cutting plate. The thickness of cutting should be within the optimal cutting range of the power supply, not the maximum cutting thickness of the power supply. In addition, choose a suitable air compressor, when the air compressor can not meet the cutting requirements, first check the output pressure on the air compressor display and then check whether the adjustment of the air filter pressure relief valve is correct. The main reasons of insufficient pressure of air compressor are insufficient air input, unobstructed air passage and oil pollution in solenoid valve. Regular maintenance of the air filter pressure relief valve should be carried out to ensure that the input air is dry and oil-free.

When the working pressure can not reach the pressure required by the NC plasma cutting machine, the speed of plasma arc ejection will be weakened, unable to form high-speed, high-energy plasma arc, poor quality of the incision, incision tumors or even cut impermeable phenomenon, users need additional attention.

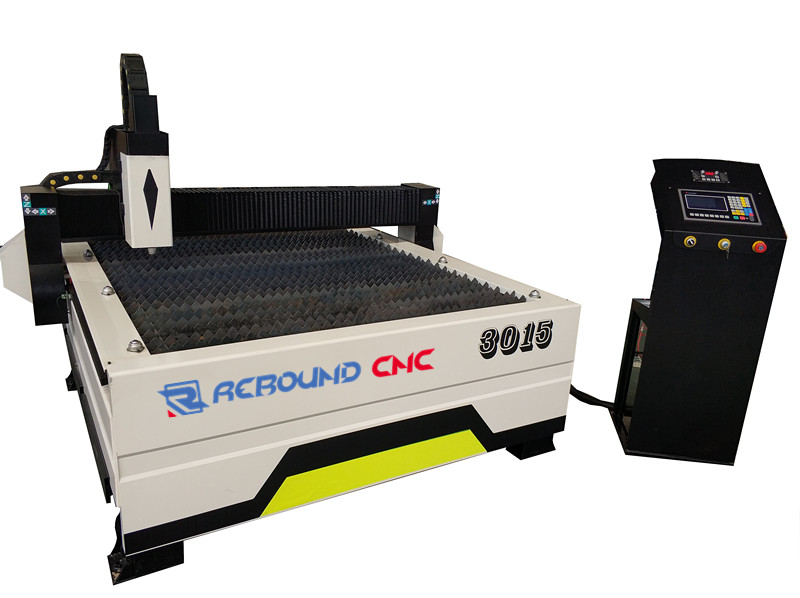

Jinan REBOUND CNC MACHINE has sorted out some matters needing attention in the safe operation of NC plasma cutting machine for reference.

A and CNC plasma cutting machine can not leave when cutting operation.

B, check whether the gas path is normal without leakage before starting.

C, numerical control plasma cutting machine cutting process in case of emergency, to press the red emergency switch immediately to prevent accidents and equipment damage.

D, close all the air valves of the cutting machine before leaving work, and put the remaining gas in the air pipe.

CNC plasma cutting machine operation slightly dangerous, but as long as the safety work is in place, the probability of accidents is very small, so understanding and doing a good job of safety work is very important and necessary.

A, prevent injury

1, after each cutting is completed, the cutting gun should be raised to a higher position to avoid damaging the steel plate and causing damage.

2, no electronic devices in the control cabinet should be touched under the electrified condition to avoid electric shock.

3. CNC plasma cutting machine beam in moving to ensure that there is no one or other objects in front, to prevent collision accidents.

B, prevent electric shock.

1, do not wet your hand to touch any switches and buttons to prevent electric shock.

2, do not electrified to line up or replace electrical components, otherwise you will be electrocuted or injured.

3. Maintenance staff with corresponding technical qualifications shall maintain the equipment strictly in accordance with the technical requirements of electrical maintenance. In case of accidents.

4. When the power is on or the machine is running, do not touch any electrical components in the electric cabinet and console of the CNC plasma cutter.

C, prevent fire.

1. The air source of the cutting machine should be far away from the open fire and put carbon dioxide or other corresponding fire extinguishing devices around it.

2. The material used in cutting machine of NC plasma cutting machine is inflammable gas such as acetylene, propane, liquefied gas and so on.

3, control staff in the fire control should be timely control, in order to avoid fire. Therefore, we must check CNC plasma cutting machine regularly whether the whole gas path is sealed well.

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China