The use of CNC flame cutting machine involves electrical, gas and related preparatory work items, generally in the process of delivery by the manufacturer to provide detailed instructions and require the use of enterprises and operators to strictly observe. In order to achieve the desired cutting effect of flame cutting, we must have some preparatory work before cutting. Considering the different operating conditions of the equipment, we summarized the three-point inspection work and related requirements for reference.

1. Check the CNC flame cutting machine each gas path, valve, whether there is no leakage, gas safety device is effective.

2. check whether the gas inlet pressure provided by CNC flame cutting machine meets the requirements.

3. check whether the power supply voltage of CNC flame cutting machine meets the requirements.

4. Before cutting with NC flame cutting machine, the workpiece is first padded flat, and a certain gap is left under the workpiece to facilitate the blowing of iron oxide slag. When cutting, in order to prevent the operator from being burned by spattered oxide slag, it must be covered with baffles if necessary.

5. adjust oxygen to the required pressure. For shooting suction cutting torch, check whether the cutting torch has the ability of shooting. The method of inspection is to first remove the acetylene intake hose and bend it, then open the acetylene valve and preheated oxygen valve. At this time, the finger on the cutting torch acetylene through the trachea joint, if the finger feel a pull and can be adsorbed on the acetylene intake pipe joint, indicating that the CNC flame cutting torch has ejection and suction ability, can be used; otherwise, the cutting torch is not normal, can not be used, should be checked and repaired.

6. check the flame line of the NC flame cutting machine. The method is to ignite the flame and adjust the preheated flame properly. Then open the cutting oxygen valve and observe the shape of the cutting oxygen flow. The wind line should be a straight, clear cylinder with appropriate length. Only in this way can the surface of the workpiece be smooth and clean, and the width and the width are uniform. If the wind is irregular, close all valves and trim the inner surface of the nozzle with a needle or other tool to make it smooth.

7. Check whether the work site meets the safety requirements, cutting torch, oxygen cylinder, acetylene bottle rubber pipe, pressure gauge, etc. are normal, gas cutting equipment in accordance with the operating procedures.

8. the power of the preheated flame should be adjusted according to the thickness of the plate. The neutral flame should be adopted in the flame.

Before using NC flame cutting machine, the thickness, cutting material and gas parameters of flame cutting need to be considered comprehensively. In order to ensure the cutting quality, we need to prepare in advance.

CNC flame cutting machine cutting out the quality of the workpiece, part and the accuracy of equipment related, the other part and the operator's tempering has a direct relationship, flame cutting according to the different cutting gas is also different, many enterprises buy two equipment, while cutting a workpiece, the effect is still However, the ultimate reason is that the operator is not in place in regulating the fire link, in order to let enterprises give full play to the value of the use of CNC cutting machine.

To make good use of NC flame cutting machine, first of all, it is necessary to master the cutting gun flame skillfully. The key to adjusting the flame is the gas source. Oxygen is mostly supplied by pipelines in general enterprises. The purity and pressure of oxygen can generally meet the requirements of use, but most of the gas is bottled gas, 30 kg of a bottle gas, in the scale of 5 machines and 5 streams. The use time is about 2 hours. In this way, the gas source must be replaced halfway, which leads to the fluctuation of gas pressure, which directly affects the gas flow and leads to abnormal cutting. In addition, in order to ensure the integrity of the existing equipment, we should inspect the pipelines and joints regularly on the basis of operation rules. Leakage, lubrication of bearings, pin holes and other places, cutting nozzles, cooling pipes and other cleaning, to complete some routine work, to ensure normal operation, and then to improve, to improve the effect.

There are also doubts in the use of CNC flame cutting machine. When producing high carbon steel, it is very difficult to observe the work of flame cutting machine, and the completion of cutting process. Learn and research and master many aspects of knowledge.

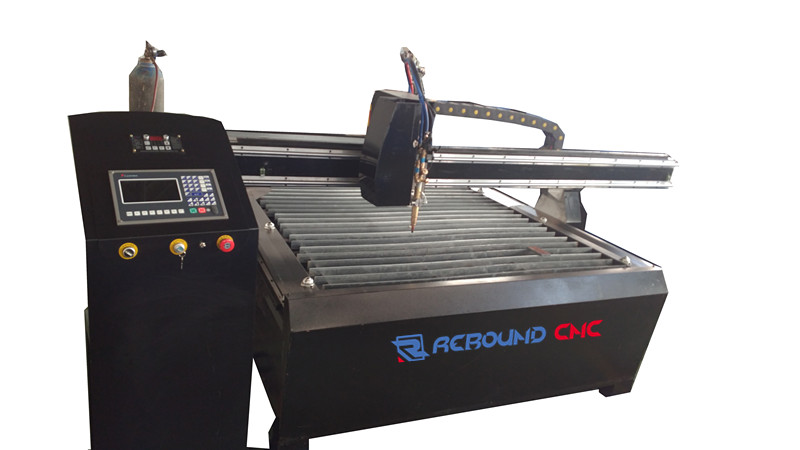

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China