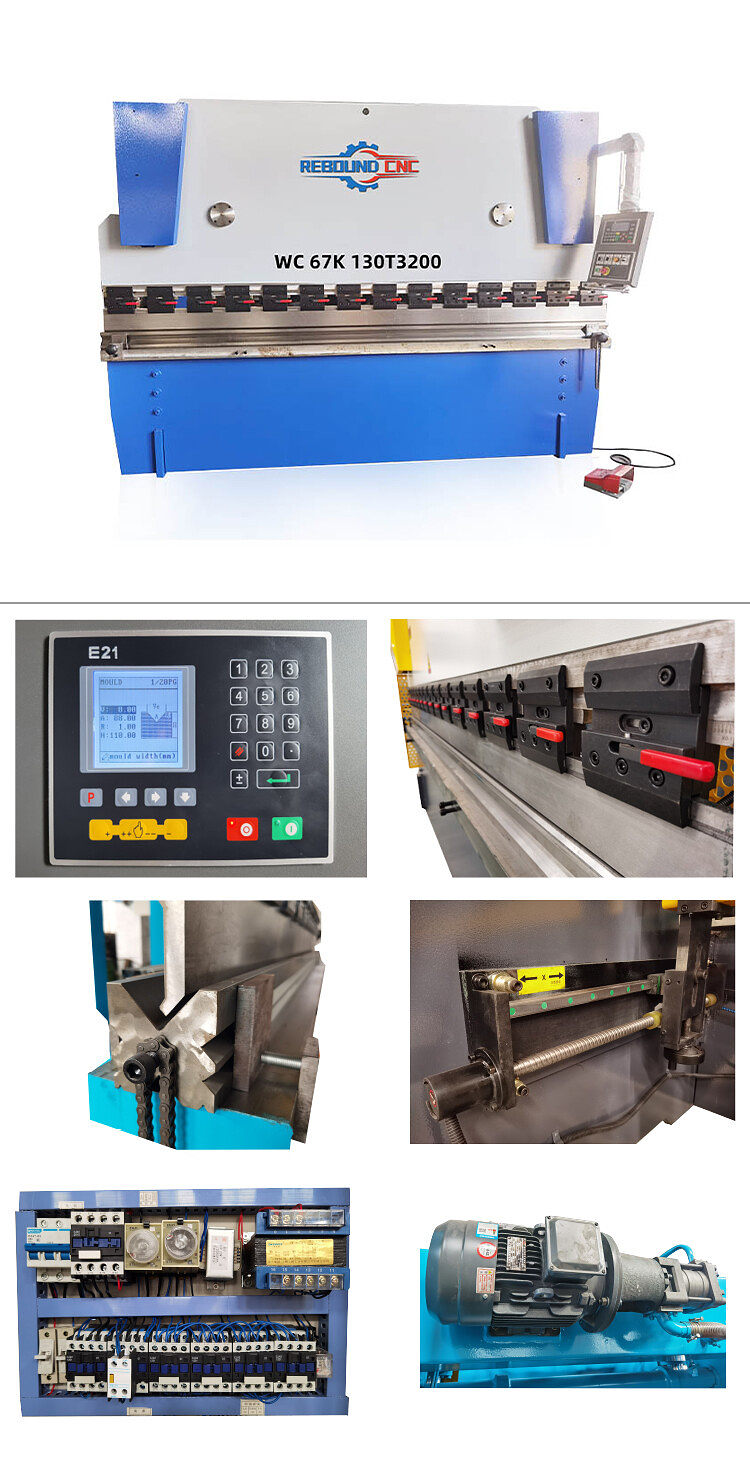

CNC press brake machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench, and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through hinges. Connected, the base is composed of a seat shell, a coil, and a cover plate. The coil is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate.

1.In view of characteristics of shearing machine, photoelectric encoder is equipped to display position of back gauge and dead block. Special functions like one side positioning display and spindle allowance offset are

available to ensure unity for displayed position and actual position of back gauge.

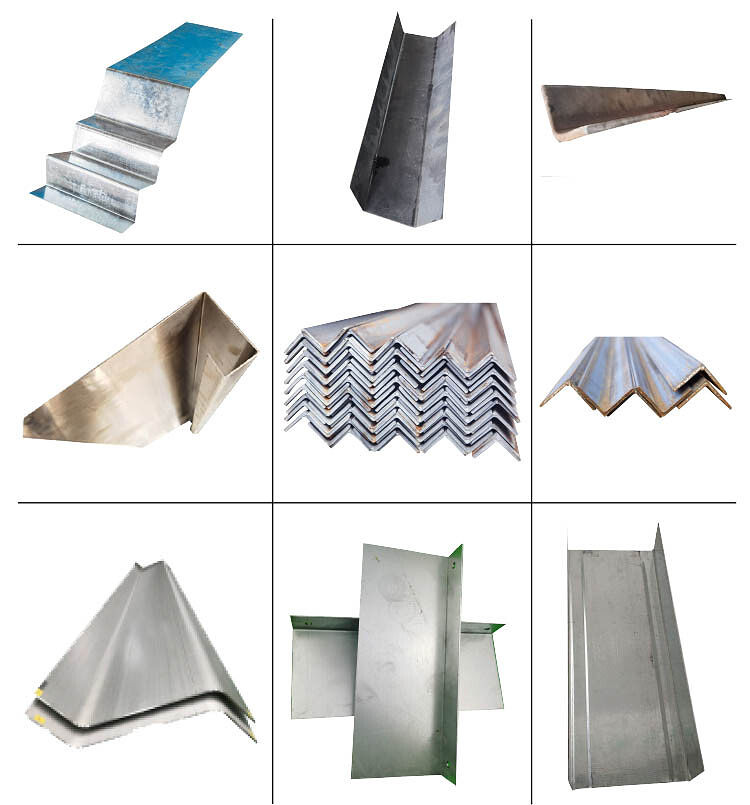

2.The quick clamping of the bending machine mold is not only convenient for clamping the mold and adjusting the uniform force of the mold, but also has the function of preventing the upper slider from being damaged. A bending machine tool equipment company said that the tool was directly fastened to the slider with screws without installing bending machine die clamping plates, and long-term use could lead to deformation of the slider. If the bending parts are relatively long, the situation will be better.

3.When the bending machine is used, if different bending machine dies need to be equipped according to the different plates to be bent, the processing parameters of the bending machine die must be understood first, and then the matching dies can be selected. Upper mold part: straight sword knife, straight sword (large, small) scimitar, gooseneck (large, medium, small) scimitar, 30 degree sharp knife, flattening knife, simple mold, special mold, arc cutter.

4.Based on the principle of hydraulic transmission, the implementation elements (cylinder and plunger or piston) are simple in structure, easy to complete large task pressure, large task space and long task travel, so they have strong compliance and are easy to suppress large workpieces or longer and higher workpieces. The extra maximum pressure of the press can occur at any position of the outer stroke. The pressure can be

maintained for a long time at the down conversion point, which is very necessary for many processes.

5.The main electrical components of the machine are all famous Chinese brand.

6.This product has a strong clamping force and stable clamping; Easy adjustment and high efficiency; The stiffness is higher than that of a long claw, and the accuracy can be maintained for a long time; The chuck has a simple structure, light weight, small moment of inertia, and low energy consumption.

2. The machine's mechanical stop and back gauge are equipped with counters to display the stroke, which is convenient and intuitive to use. This machine sample can realize procedures such as rapid descent, slow descent and pressure, pressure maintenance, and rapid return, which is convenient and reliable.

3. The working accuracy and repeated positioning accuracy are high, and the anti-eccentric load performance is good. The upper mold has a fine-tuning mechanism, which can easily adjust the height position of each part of the upper mold to ensure that there is a uniform gap between the upper and lower molds during bending work, which can significantly improve the bending angle and accuracy.

4. The bending pressure is based on the thickness of the plate, the size of the opening of the lower die, and the width of the sheet to be folded, and the required bending force can be found in the sheet metal bending pressure gauge.

|

NC system |

E21 controller |

|

Main electric components |

Schneider |

|

Oil pump |

Jiangsu Qidong |

|

Hydraulic integrated system |

Shanghai Gemei |

|

Oil cylinder seals |

Taiwan Dingji |

|

cylinder |

Taiwan Yingfa |

|

reducer |

Jiangsu taixing |

|

Solenoid valve |

Shanghai Gemei |

|

High pressure pump |

Sunny |

|

Motor |

Rongcheng |

|

valve |

Rexroth |

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China