CNC router machine is a short name, generally refers to computer numerical control engraving machine. It is a mechanical equipment controlled by a computer, which can carve different reliefs on the workpiece according to the edited engraving path, and cut different workpieces, etc. It is a new fully automated mechanical equipment. It is also called CNC engraving machine. According to different processing materials, engraving machines are divided into woodworking engraving machines, stone engraving machines, advertising engraving machines, etc. According to different processing characteristics, they are divided into plane engraving machines, three-dimensional engraving machines, etc.

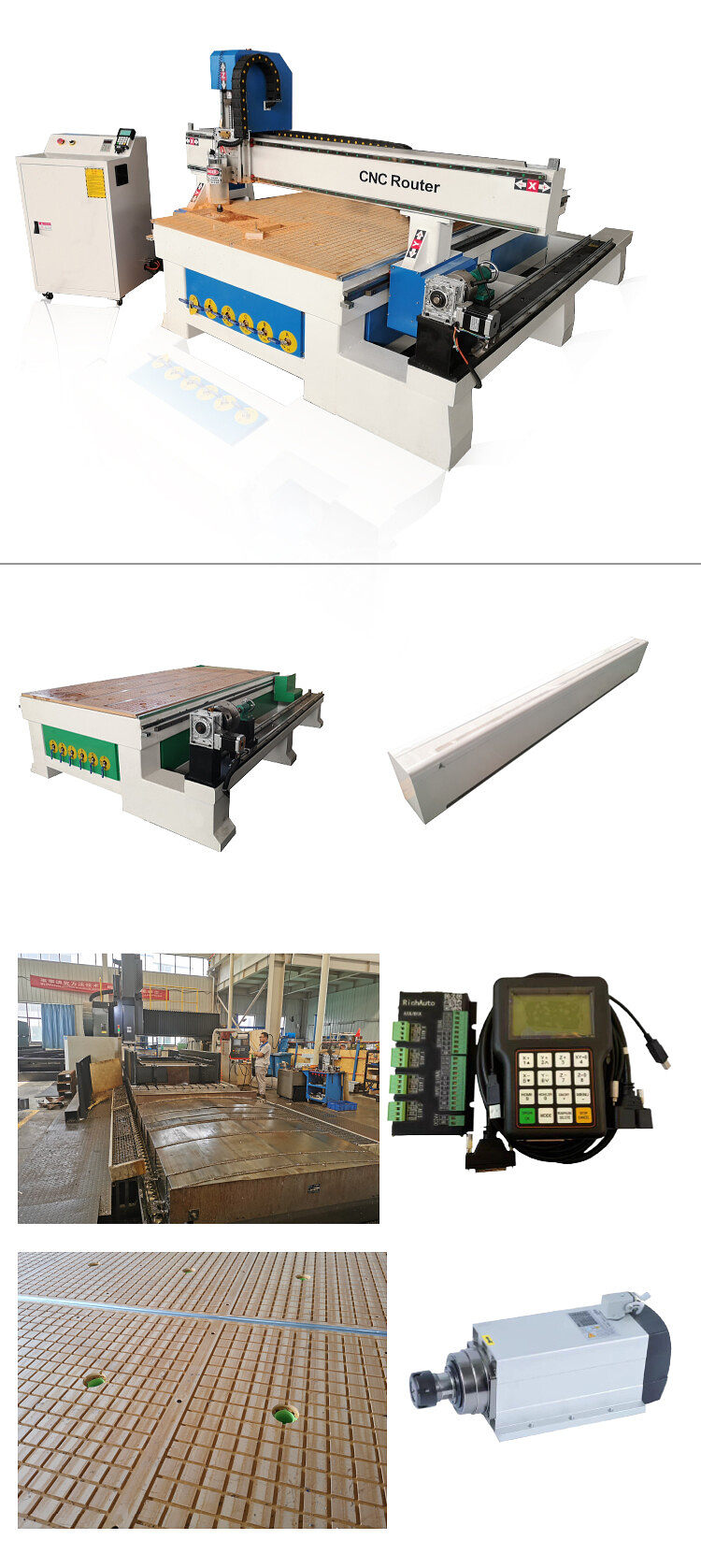

1.High strength machine bed is more stable and durable.After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

2.Professional industrial steel material.Good steel property, light weight, and small inertia. Improve cutting speed and life.

3.The machine steel structure is processed by precision machine tool, solid and reliable, durable.

4.The new three-axis motion mode achieves comprehensive control. Support XYZ driver and spindle frequency converter processing error alarm prompt function. Large storage space, strong USB compatibility, and fast reading speed. Intelligent file checking function. Equipped with parameter backup and recovery functions, effectively preventing the loss of important parameters.

5.The advantage of vacuum adsorption table is that even irregular boards can still be tightly fixed on the table of CNC lathe, ensuring that there is no vibration that affects the carving effect during the carving process. Obviously, the vacuum adsorption stage will improve the carving accuracy to a certain extent, especially for thinner and lighter boards.

6.The air-cooled high-speed spindle adopts four bearings and a pure copper motor, with strong power. Fan cooling automatically reduces the heating caused by high-speed rotation.

|

Model |

RB-T1325 |

|

Working size (X Y Z) |

1300×2500×200mm |

|

Table size |

1440×3040mm |

|

Rotary size |

200*2500mm |

|

Operating system |

RICHAUTO A11 |

|

Motor |

LEADSHINE stepper/servo motor |

|

Spindle |

6.0 kw |

|

Vacuum pump |

5.5kw |

|

Vacuum cleaner |

3kw |

|

Table |

Vacuum adsorption +T-slot table |

|

Max. running speed |

50 m / min |

|

Command |

G code |

|

Resolution |

0.01mm |

|

X Y Transmission |

Rack and pinion transmission, HIWIN square linear guide |

|

Z Transmission |

Taiwan TBI rolling ball screw, HIWIN square linear guide |

|

Collet size |

ER32, available diameter of cutter φ3.175-φ16mm |

|

Working power |

380V/50-60Hz, 3 Phase 220V/50-60Hz, 1 Phase |

|

Max. Power Consumption |

17 kw |

|

Net weight |

1200 KGS |

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China