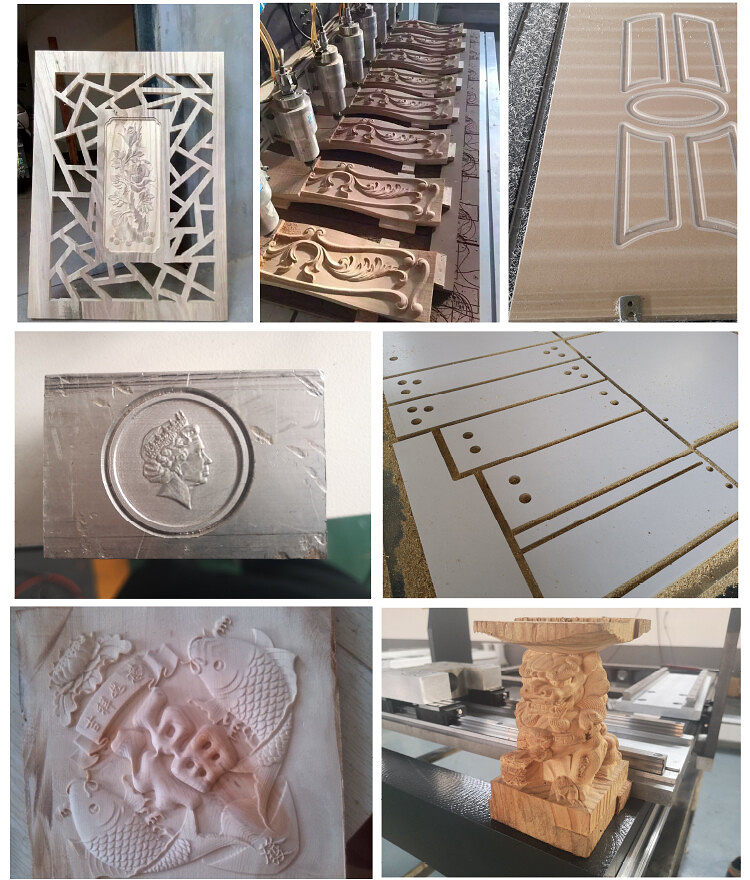

CNC router machine is a short name, generally refers to computer numerical control engraving machine. It is a mechanical equipment controlled by a computer, which can carve different reliefs on the workpiece according to the edited engraving path, and cut different workpieces, etc. It is a new fully automated mechanical equipment. It is also called CNC engraving machine. According to different processing materials, engraving machines are divided into woodworking engraving machines, stone engraving machines, advertising engraving machines, etc. According to different processing characteristics, they are divided into plane engraving machines, three-dimensional engraving machines, etc.

1.High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

2.Professional industrial steel material.Good steel property, light weight, and small inertia. Improve cutting speed and life.

3.The machine steel structure is processed by precision machine tool, solid and reliable, durable.

4.The system uses imported chips, stable performance, fast processing speed. 3 times the gold plating thickness, 100,000 plug-in and pull-out times, stable data transmission. 15-pin interface, strong anti-interference.

5.The water-cooled spindle adopts pure copper coil, P4 bearing, and dynamically balanced ER20 nut, with stable and reliable performance.

6.Large torque: The latest magnetic circuit optimization design scheme is adopted to achieve a small volume and large torque. Low heat generation: The use of high-grade and high-performance silicon steel sheets reduces the heat generation of the stepper motor. High stability: The core components are made of imported materials to ensure the smooth and reliable operation of the motor. High consistency: Large-scale automated production lines and strict quality management systems ensure the batch consistency of products.

1.T-slot table. You can fix the work piece by clamp.

2.Frame is welded with seamless steel structure; processed by high temperature tempering. treatment andvibrating stress relief (VSR) to reduce residual stress; and it is supported by with adjustable leveling feet.

3.Beam is made of steel. A steel beam is superior to a aluminum in its ability to suppress and absorb the forces created during cutting. It is internally ribbed to stiffen the assembly; this design is minimizing the vibration while increasing accuracy and repeatability.

4.The X and Y axis motion is via a rack and pinion drive, which is hardened for extremely long life andground for a very good accuracy; The Z axis is driven by a hardened rolling antibacklash ball screw.

5.Each axis of motion is supported on high precision linear guide ways. Hiwin linear guides allow for higherfeed speeds and a better quality of cut.

6.The Y-axis uses a dual drive, one for each side of the gantry.

7.Well compatibility: CAD/CAM designing software e.g. Type 3/Artcam/UcanCAM etc.

8.Has the function of re-carving after break point and power failure.

9.Configured with dsp control, user-friendly operation.

10.All the linear guides are centrally lubricated from a central system.

|

Model |

RB-1325 |

|

Working size (X Y Z) |

1300×2500×200mm |

|

Table size |

1440×3040mm |

|

Operating system |

NC studio computer controller |

|

Motor |

LEADSHINE stepper motor |

|

Spindle |

3.0 kw, water cooling |

|

Table |

T-slot |

|

Max. running speed |

50 m / min |

|

Command |

G code |

|

Resolution |

0.01mm |

|

X Y Transmission |

Rack and pinion transmission, HIWIN square linear guide |

|

Z Transmission |

Taiwan TBI rolling ball screw, HIWIN square linear guide |

|

Collet size |

ER25, available diameter of cutter φ3.175-φ16mm |

|

Working power |

380V/50-60Hz, 3 Phase 220V/50-60Hz, 1 Phase |

|

Max. Power Consumption |

7 kw (spindle included) |

|

Net weight |

1000 KGS |

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China