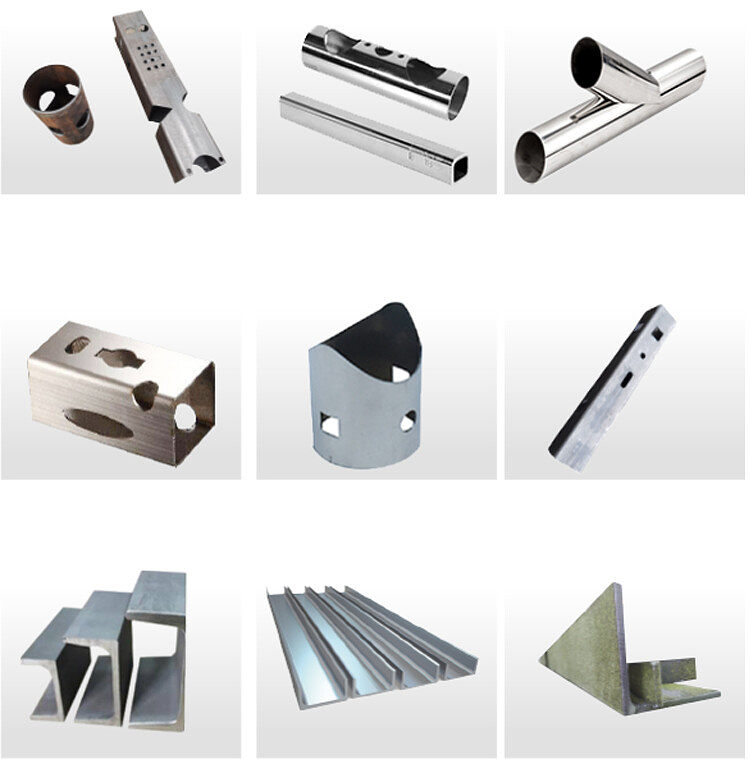

The plasma tube cutting machine is developed and produced to meet the requirements of intersecting line cutting. It can complete the cutting of round tubes, square tubes, channel steels, angle steels and other metals. The plasma cutting machine has the characteristics of wide cutting range, fast cutting speed, and high work efficiency. The future development direction lies in the improvement of plasma power supply technology and the cooperation between CNC system and plasma cutting, such as power supply power. The improvement can cut thicker plates; the improvement and improvement of fine plasma technology can improve the cutting speed, cutting surface quality and cutting accuracy; the improvement and improvement of the CNC system to adapt to plasma cutting can effectively improve work efficiency and cutting quality.

1.The machine steel structure is processed by precision machine tool, solid and reliable, durable.

2.The machine bed structure is made of welded steel tube and has a stable structure.

3.This system is suitable for the automated processing of square tubes, round tubes, and oval tubes with or without grooves. It can be done without programming, and comes with a standard library of square tubes, round tubes, and oval tubes. It supports four square tube modes, and the library includes: multiple truncation methods, straight cutting of circular holes, rectangular holes, corner cutting, corner rectangular hole cutting, L-shaped installation hole cutting, and oblong holes. It can perform online programming of straight line, arc corner cutting, and is illustrated with pictures and texts.

4.Metal cutting position can be arbitrarily selected by wireless remote control, which greatly facilitates the user's operation.

5.The speed parameters can be modified according to the power supply and lifting mechanism. The circuit adopts SMD technology, and there is no adjustable device inside. The full digital control technology ensures that the product has a high degree of reliability. The operation is simple, and the two sets of digital tubes display the set arc voltage and the actual arc voltage respectively, which is simple and intuitive. The interface is simple and easy to control, suitable for all plasma cutting CNC systems, and can also be used alone.

6.Support Window XP/Win7/Win8/Win10 operating system; Support multiple languages; Beautiful software interface, no software training required; Support round tubes, square tubes, rectangular tubes, waist-shaped

tubes; Import a variety of 3D files (*.prt, *.ipt, *.sldprt etc); Can load CAD files on the tube.

TECHNICAL PARAMETERS:

|

Model |

RB 6000, RB 12000 |

|

Working Voltage |

220V±15%, 50/60Hz, 1PH, CNC machine. 380V±15%, 50/60Hz, 3 PHS, Plasma power |

|

Cutting Size |

Diameter: 200mm, 300mm, 400mm Length: 6000mm/12000mm |

|

Maximum Speed |

12000mm/min |

|

Plasma Cutting Thickness |

0-50mm (Depends on different plasma power) |

|

Plasma Power |

63A/120A/200A/300A/400A |

|

Packing size |

7000*1500*1800mm/ 13000*1500*1800mm |

|

Gross weight |

2500KG/4500KG |

|

Control System |

STARFIRE |

|

Driving System |

HCFA servo driving system |

|

Relay Accessories |

Schneider |

|

Torch Height Controller |

Automatic |

|

Guide Rail |

HIWIN square orbit, 20mm |

|

Transmission Method |

Gear transmission |

|

Chuck control method |

Pneumatic and electric |

|

Cutting Torch Lifting Mode |

Arc Voltage Increase |

|

Plasma Torch |

RB-X100/RB-X200 |

|

Software |

STARPIPE |

|

File output Mode |

USB interface |

|

Command Code |

G code/*.MMG/*.PLT/*.eng |

|

Packing Type |

Standard plywood case |

|

Lubrication |

Automatic Electric |

Contact: Jinan Rebound CNC Machine Co.,Ltd.

Phone: 0086-13296443055

Tel: 0086-0531-88804682

Email: info@reboundcnc.com

Add: Lotus Road, Li Cheng District, Jinan City, Shandong province, China